Enhancing Electronics Manufacturing Efficiency with the Electronic Parts Feeding System

The Booming Electronics Market and Electronic Parts Feeding System

The global electronics market, bolstered by the implementation of automation system, is worth over $4.7 trillion and is expected to grow at a CAGR of 7.8% from 2022 to 2028. The soaring demand for electronic devices from consumers and businesses worldwide is fueling this impressive growth.

Embracing Automation in Electronics Manufacturing

To enhance efficiency, productivity, and product quality, the electronics industry is increasingly turning to industrial automation, with robots playing a crucial role. These robots are often enhanced by advanced electronic parts feeding systems. In 2021, the global market for industrial robots reached $48.3 billion, projected to experience a CAGR of 14.5% from 2022 to 2028. Among the various sectors, electronics holds a substantial 25% market share in the utilization of industrial robots. Robots are extensively deployed in electronics for tasks such as assembly, testing, welding, and painting.

Challenges in Electronic Parts Feeding Processes

Implementing an efficient electronic parts feeding system presents several challenges, including:

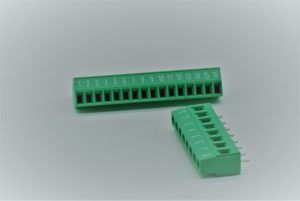

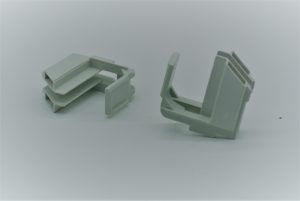

- Miniature Size: Electronics often consist of tiny components, making precise positioning and handling during feeding a daunting task.

- Irregular Shapes: Some electronic products may have complex or irregular shapes, increasing the risk of jamming and production interruptions in the feeding system.

- Sensitivity: Electronic components can be extremely sensitive to vibrations, shocks, or electrostatic discharge, necessitating delicate handling in the parts feeding system to avoid damage.

- High Production Speed: The electronics industry often requires high-speed production, adding complexity to the rapid and efficient feeding of items.

- Component Variety: Electronics encompass a wide range of different components, each with unique feeding and handling requirements in the parts feeding system.

- Complex Assemblies: Electronic part assembly can be highly intricate, demanding accurate positioning and connection of numerous components in the feeding system.

- Quality Control: As electronics are often used in sensitive equipment, ensuring quality during part feeding in the system is critical to prevent defects or assembly errors.

Complex

Flat

Videos

50 x 1 mm

90 x 10 mm

15 x 10 mm

35 x 15 mm

The Role of Flexible Feeding Systems in Electronics

With the advent of Industry 4.0, flexible feeding systems have become pivotal in electronic parts feeding. A versatile feeder capable of handle items ranging from 1 to 300 mm offers several key benefits:

- Versatility: The ability to handle various shapes and sizes of items negates the need for customized feeders for each part.

- Increased Efficiency: Reduced downtime during setup phases enhances production speed.

- Adaptability: Swift and seamless transitions between different parts optimize workflow.

Examples of Electronic Products Handled by the Feeding System

Flexible feeding systems like FlexiBowl® can accommodate a broad range of electronic parts, including:

- Relays

- Switches

- Batteries

- Microchips

- LEDs

- Sensors

- Connectors

Processes Where Flexible Feeding Systems Can Be Implemented

Flexible feeding systems are extensively used in various electronic production processes, such as:

- Assembly: In operations involving the assembly of products like electronic boards, capacitors, transistors, and microchips, flexible feeding systems ensure effective orientation and separation of parts.

- Packaging and Boxing: Using flexible feeders streamlines kit assembly.

- Quality Control: Flexible feeders present various parts to inspection devices, such as vision systems or sensors, enabling rigorous quality checks demanded by the industry.

As we know, electronic components are vital across industries. Beyond consumer electronics, they are extensively used in automotive, maritime, and aerospace domains to develop safety and control systems. In the medical field, they underpin precision tools, and in telecommunications, they've revolutionized our communication methods.

Flexible feeding is thus employed in:

- Consumer Electronics Production: These high-performance systems are used in producing computers, mobile phones, USB sticks, televisions, household appliances, audio devices, and more.

- Medical Device Production: In the medical sector, where delicate, small-scale parts are used, flexible feeding systems ensure precise and gentle handling of individual parts.

- Semi-finished Productions for the Automotive Sector: In the automotive industry, flexible feeding systems can supply electronic items used in vehicle control systems, entertainment electronics, and safety devices.

Why Choose Our Parts Feeding System?

FlexiBowl® is a technology adept at seamlessly and reliably handling small-sized parts. With its expansive gripping area, it ensures optimal part distribution. Its streamlined and functional design makes FlexiBowl® a dependable and efficient system, minimizing maintenance interventions. The integrated backlighting function allows the vision system to precisely identify a wide range of varied products. Its antistatic belts make it suitable for applications in the electronics sector.

These features have led numerous companies to select FlexiBowl® for their production processes.

Main end users